Gallery

-

Biobased Foam – DeCoto

Biobased Foam – DeCotoThe foam material for every application - Biobased Foam DeCO2

DeCO2 BIOBASED FOAM

The biobased foam material not only achieves carbon reduction and environmental protection but also can be applied to a variety of needs.The application of DeCO2 Biobased Foam is the same as the general EVA foam; however, DeCO2 foam differentiates itself from ordinary EVA foam because it is a composite of renewable materials (bamboo, wood, rice husk) and recycled plastic resin, which is sustainable, carbon-reducing, and environmentally friendly.

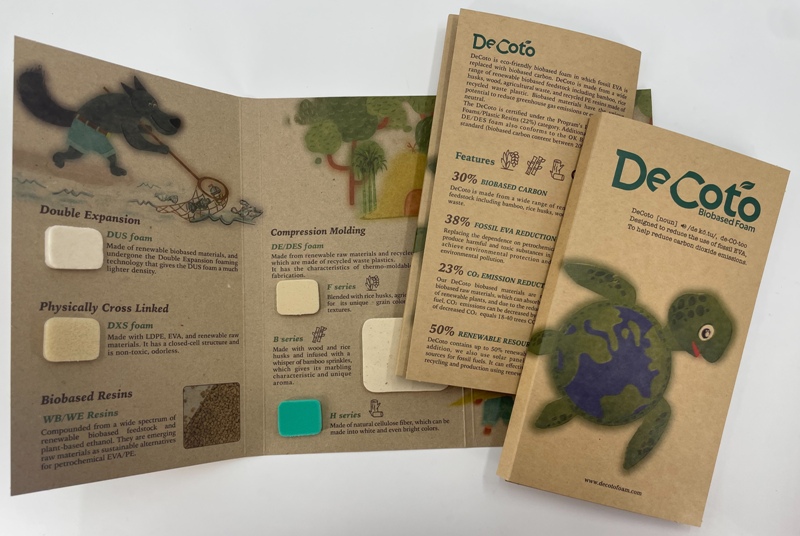

▲2022 new catalog – Biobased foam DeCO2

We’ve successfully expanded DeCO2 biobased foam categories by incorporating different foaming techniques such as Double Expansion Foaming and Physically Cross-linked Foaming. Furthermore, we also offer Biobased resins for a variety of applications.

The specifications (depending on foam formulation) and applications are as follows:Compression Molding

-

Density (g/cm3):0.06-0.59

-

Thickness (mm):50

-

Foam structure: Closed-cell

-

Application:Fitness accessories / Sports accessories / Yoga accessories / Massage accessories / Protection pads

-

Density (g/cm3):0.03-0.06

-

Thickness (mm):100

-

Foam structure: Closed-cell

-

Application:Protection pads / Water (sports) equipment

- Density (g/cm3):0.03-0.45

- Thickness (mm):12

-

Foam structure: Closed-cell

-

Application: Outdoor pads / Liner pads

- Density (g/cm3): Adjust as needed

- Thickness (mm): Adjust as needed

- Foam structure: Closed-cell

- Application: Doesn't limit the scope of application.

For more information on DeCO2 biobased, please click here.

If you have further inquiries on product development using our proprietary DeCoto biobased foam, please feel free to contact us. -

-

Biobased Foam – DeCoto

Biobased Foam – DeCotoGreen Energy plan of Chiayi Taiwan plant

Alternative energy sources for fossil fuels SOLAR PANELS

Hope you are keeping safe and staying well for 2021.

Today, we are excited to share with you the news that our long-planned new Chiayi plant has finally been completed in 2021!Since the launch of our proprietary biobased foam materials – the DeCO2 foam, we have discovered that there has been a profound resonance for eco-friendly materials and environmental protection, worldwide. Hence, we were determined more than ever set up solar panels in our Chiayi plant as an alternative energy resource for fossil fuels. These solar panels provide not only the required in-house electricity but also the energy needed for our foam production lines.

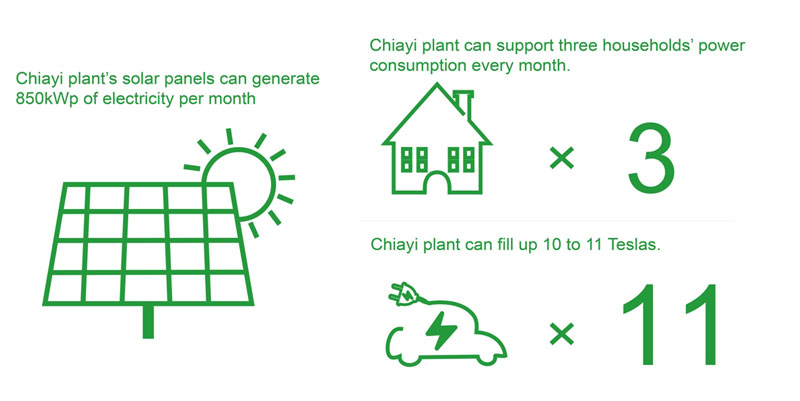

According to our Green Energy report, our new Chiayi plant’s solar panels can generate 850kWp of electricity per month. To put it into perspective, in Taiwan, a single household consumes, on average, 287kWh per month – EVA Glory’s Chiayi plant can support three households’ power consumption every month. In other words, if a Tesla needs 76kWh to be fully charged, then we can fill up 10 to 11 Teslas, easily!

-

Biobased Foam – DeCoto

Biobased Foam – DeCotoUSDA Certified Eco-friendly Biobased DeCO2 EVA/PE Resins Series

Eco-friendly Biobased DeCO2 EVA/PE Resins Series

EVA Glory's DeCO2 EVA/PE Resins series are made from a wide spectrum of renewable biobased feedstock, such as bamboo, rice husk, agricultural waste, and plant-based ethanol, which are not eligible for food or feed production. Not only are they the emerging raw materials of the foam manufacturing industry, they have also become the materials of choice for environmental sustainability and carbon reduction awareness.Using DeCO2 Resins in foam production reduces carbon emission and your environmental footprint as it replaces conventional fossil EVA and PE, without compromising on performance and quality in the final product. Foams made with the DeCO2 Resins have excellent post-processing performance that meets a wide variety of converting processes. More importantly, it is an environmentally friendly material, and we offer creative solutions to meet your specific converting requirements.

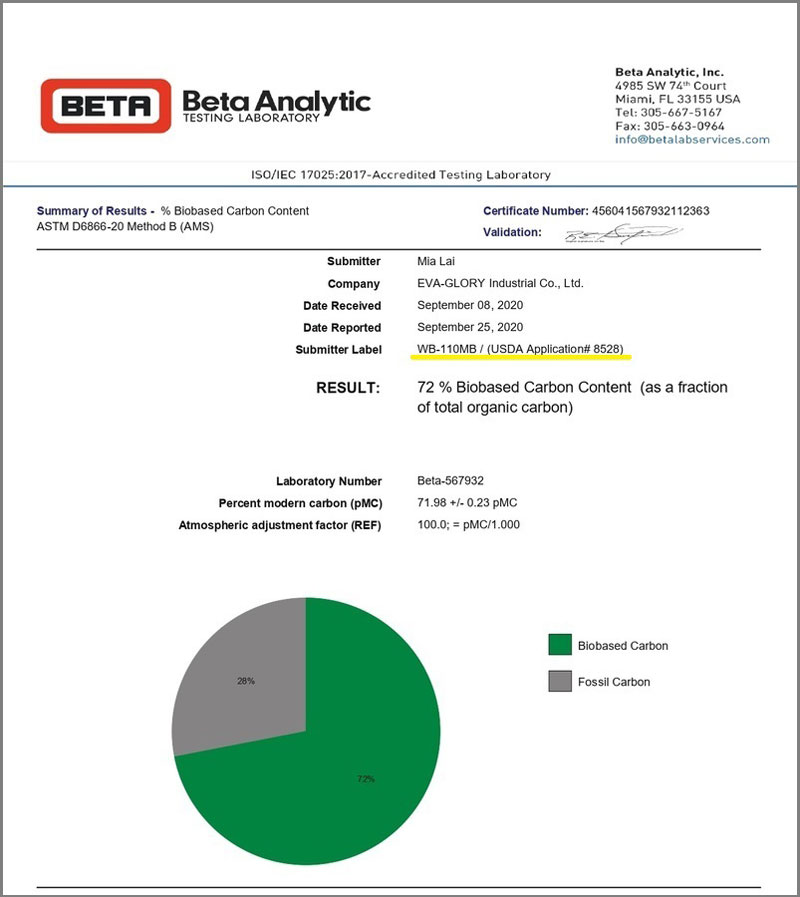

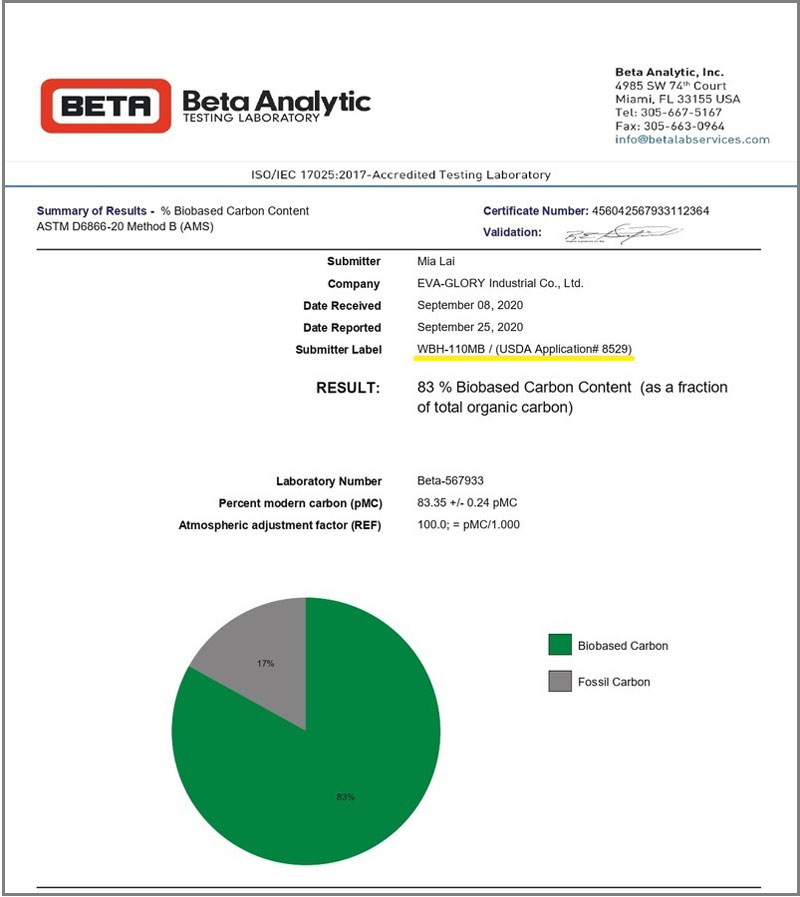

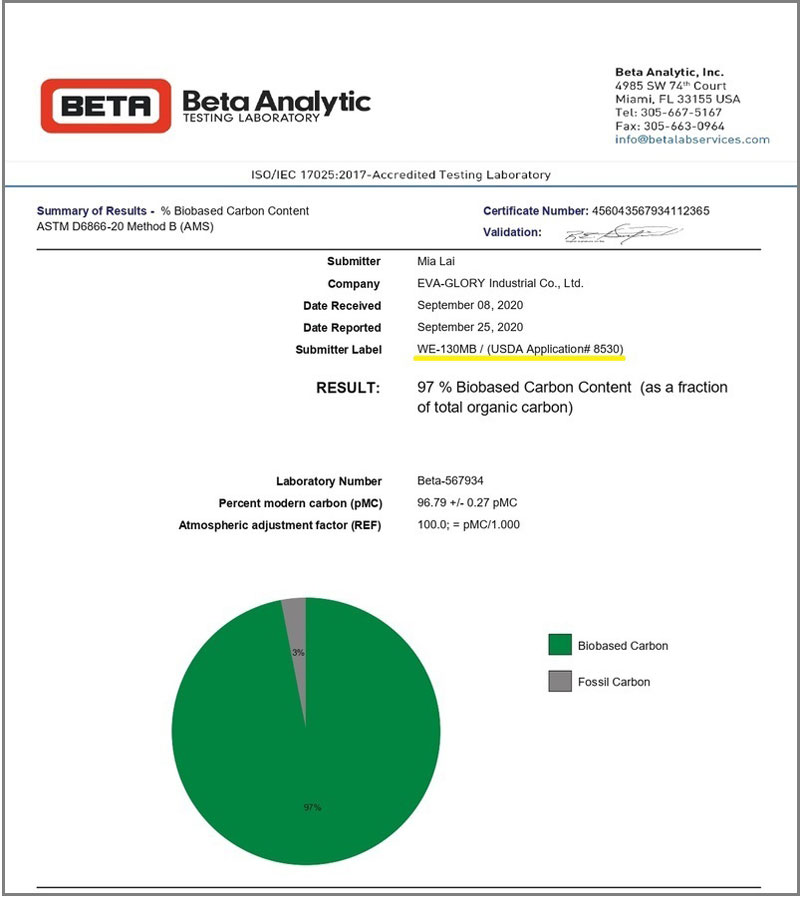

The DeCO2 Resins series contain Biobased Carbon content ranging from 70% to more than 90% as tested by Beta Analytic, Inc. DeCO2 Resins series conforms to USDA BioPreferred Program under category of Intermediates-Plastic Resins (22%). For detailed information, please click links or as shown below.

WB-110MB

WBH-110MB

WE-130MB

-

Biobased Foam – DeCoto

Biobased Foam – DeCotoWE ARE WITH THE FOAM EXPO USA 2021

The Foam Expo USA will be held from Jul 13 to 15, 2021.

Due to the coronavirus, we cannot participate in the Foam Expo USA in person, but we look forward to sharing with you new foam materials that reduce greenhouse gases and the use of plastic.The major foam materials and applications are as follows:

Foam material- Biobased foam: DeCO2

In order to reduce carbon dioxide emissions, DeCO2 foam is made with renewable raw materials and recycled PE resins. The latest DeCO2 series are biobased physically cross linked foam — DeCO2 DXS foam. And the biobased resins — DeCO2 WB/WE Resins. They can be used in a wide range of markets and applications.

- Recycle Foam

The goal is to reduce plastic. Recycle foam is made from foam wastes through physical or chemical technology and it’s made with even more ideal quality.

- Protection foam: Nitrex

EVA GLORY has developed Nitrex foam materials with impact protection and shock absorption through professional composite technology; hence Nitrex can maintain the ideal protective effect in the temperature range of -20°C to 40°C.

Application

- Foam injection

It is ideal for creating complex structures, such as curves and spherical surfaces that are difficult to achieve using the traditional EVA foam forming/shaping processes.

- Die ejection foam

We developed the die ejection foam that can be customized to meet customers' specific applications and requirements.

- Marine deck: Deva

Deva not only has excellent slip resistance, but also UV resistance, shock resistance, and anti-fatigue. Deva can be used to reduce noise and protect the boat surfaces against scratches, chips, and dents.

Click on the link to view more detailed foam material and production information. - Biobased foam: DeCO2

-

Biobased Foam – DeCoto

Biobased Foam – DeCotoNew Product Launch DOUBLE EXPANSION DeCO2 FOAM

The Double Expansion DeCO2 Foam – Eco-friendly and Lightweight

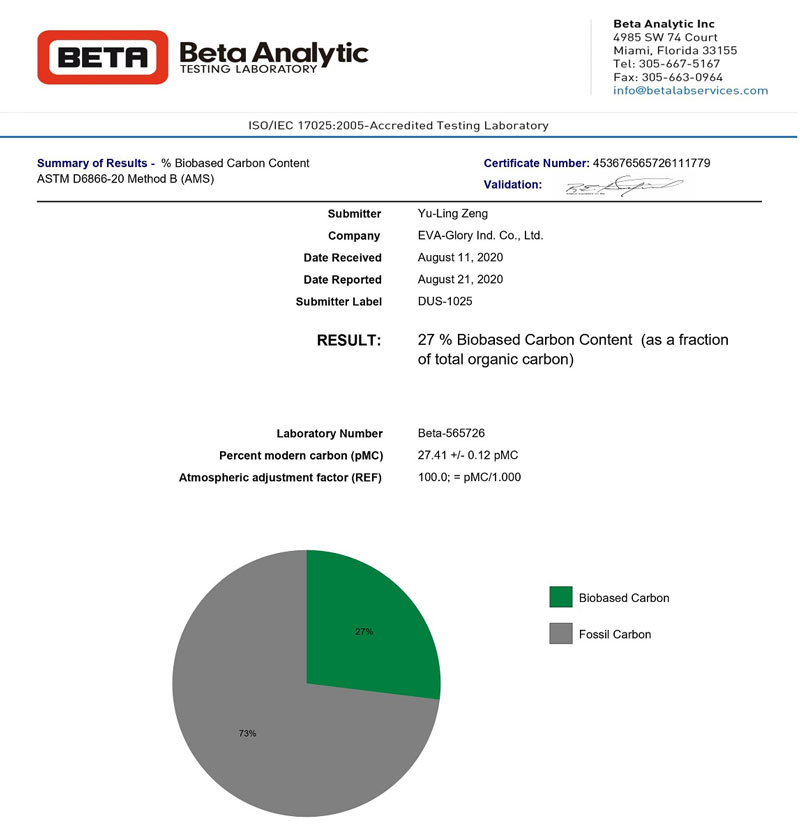

The EVA GLORY's new Double Expansion DeCO2 Foam is made using our proprietary eco-friendly compound formulation, which contains renewable biobased feedstock, and uses the Double Expansion foaming technique. The 2-Steps foaming process gives the foam its light-weight characteristic and better cost-effectiveness comparing to its sister DeCO2 Foam using 1-Step foaming process, while retaining up to 27% Biobased Carbon Content, as tested by Beta Analytic, Inc.

Feedstock:

Renewable biobased feedstock including bamboo, rice husks, straw, wood, also recycled agricultural wastes, which are not eligible for food or feed production.

Manufacturing process:

Double Expansion Foaming technique.

Our Double-Expanded DeCO2 foam is available for a wide variety of applications, and it can be customized further to meet your specific requirements.

-

Biobased Foam – DeCoto

Biobased Foam – DeCotoBiobased Physically Cross Linked – DeCO2 DXS foam

Physically Cross Linked DeCoto DXS Series

The DeCO2 DXS foam is made with LDPE, EVA, and renewable biobased feedstock which will help to reduce the carbon footprint when producing them. Our DeCO2 DXS has a smooth surface on the outside, and uniform distribution of closed-cell structures on the inside which gives the DXS foam its excellent mechanical properties and stability.

The DXS foam is non-toxic, odorless, waterproof, soundproof, shockproof, thermal resistant, and versatile for a variety of processing techniques. It can be further customized to achieve an extensive array of functions to meet customer's specific needs, such as corrosion-resistant, flame resistant, anti-mildew, anti-electromagnetic radiation, anti-static, and more.Specification(Customizable)

- Width: 600-2000mm

- Thickness: 1.5-12.7mm

- Density: 0.04-0.3 g/cm3

Inspection and certification

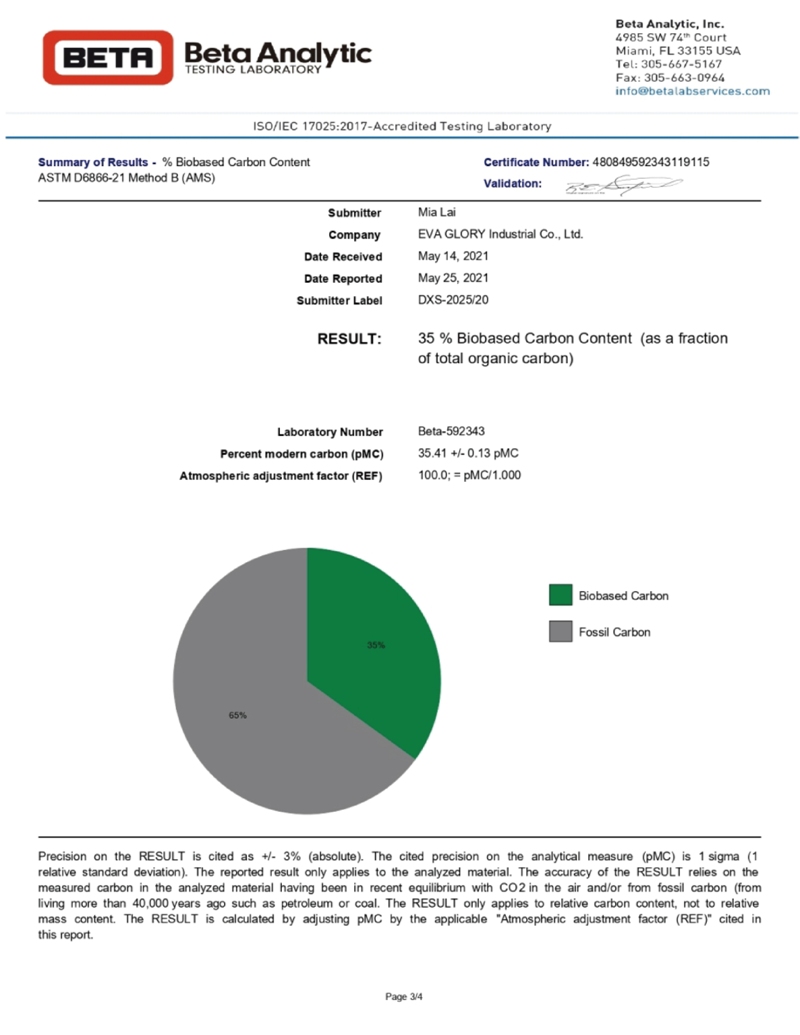

The DeCO2 DXS foam series contain Biobased Carbon content ranging from 30% to 40% as tested by Beta Analytic, Inc., and the addition of biobased feedstock does not affect the foam's basic physical properties. The DXS foam can conform to USDA BioPreferred Program under the category of Intermediates-Foams (22%), and OK biobased 1 star (between 20% and 40% biobased). In addition, we can customize different ratios of biobased carbon content for customer's needs.

Application

The DeCO2 DXS foam is widely used in a variety of applications for different sectors. It can serve as a protective and insulating foam layer for sound/heat insulation pads, bumper strips, waterproof and packaging materials. The DXS foam is an excellent material for exercise/yoga mats, water floating facilities, ski accessories, helmet liners, and equestrian vests.If you have any questions about the DeCO2 DXS foam material, please feel free to contact us.